DeadMouse

Hungry, hungry Hognose!

Well, after seeing several threads surfacing about other people either enquiring or building their own rack systems, I figured I'd show off my latest one after spending months of redesigning (in comparison to my last one) and building it. I finally finished it all up and put it into action last night. It's a great feeling building something with your bare hands from scratch and having it work the way you want.

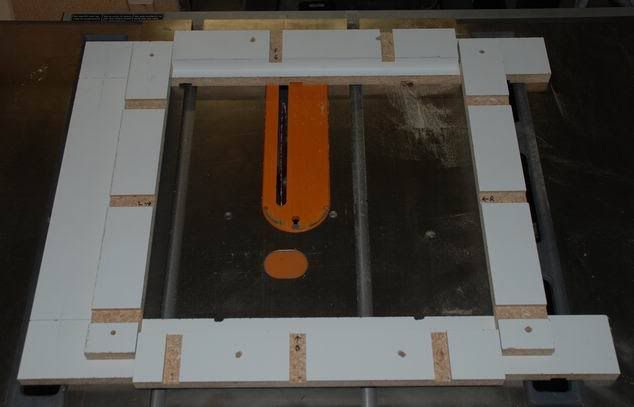

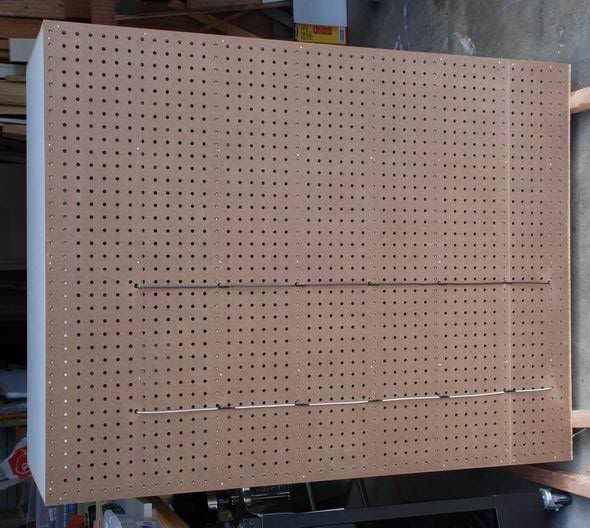

The front:

Each shelf is routed out using a jig I made to make precise cuts to fit the tile and flexwatt.

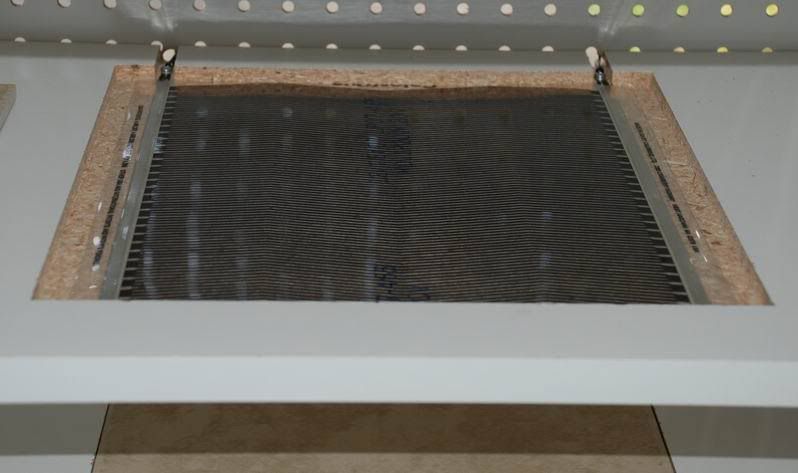

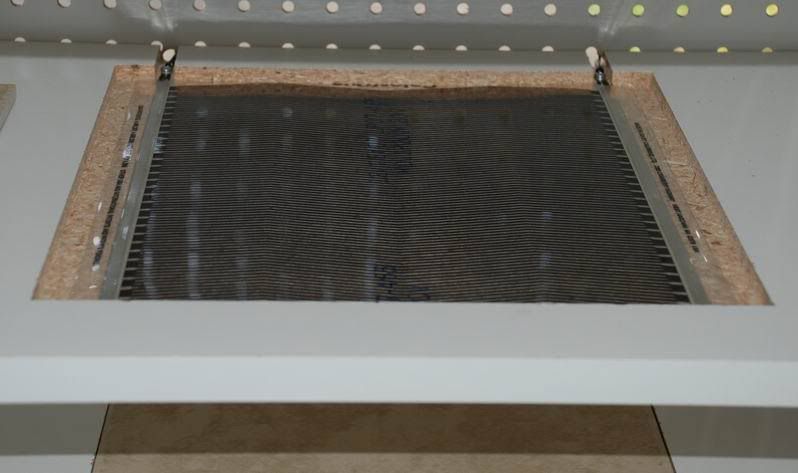

The flexwatt bare:

The flexwatt covered with tile:

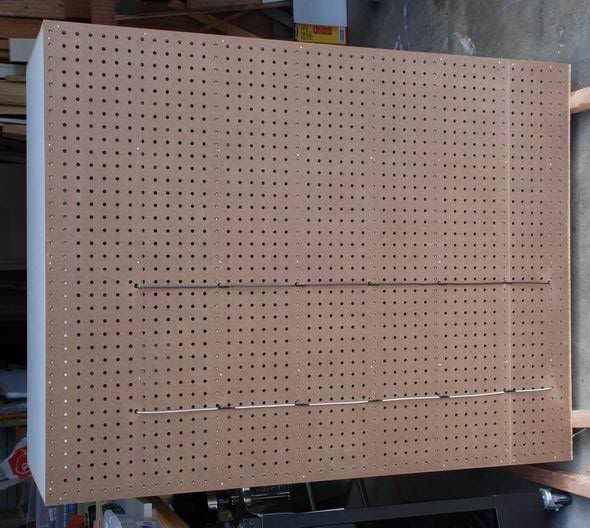

I'm not a big fan of butt joints, so I tend to dado everything!

Each shelf is dadoed:

My wiring scheme was really the biggest change in this 3rd generation of racks I've built. The top shelf wiring and bottom control shelf is the main wire while all shelves in the middle section have separate pieces of wiring soldered onto the main wire and coated using liquid electrical tape. It looks really basic on the back which is a far cry from my last rack whose wiring was a real nightmare to behold.

The back with wiring:

The bottom shelf is really a control shelf that is essentially the same as the others, only shallower using a small tub with the thermostat probe in it to monitor the temps. I once tried keeping a probe in an occupied tub heavily taped, but snakes have a funny way of fubar'ing anything you think you are clever in doing.

The bottom control section:

Each shelf is sized to house sterilite 41qt. tubs. I made a jig to help dado cut each side perfectly so that there is zero clearance between shelf and tub and yet there is no friction due to tightness, so removal is nice and smooth.

Half full with tubs:

Considering that our house has literally filled up with all of these large snake tanks, racks then became a much more idealistic solution to help alleviate the space management problems we are currently having. While it might be quicker, easier and even possibly cheaper buying a pre-made rack system, where's the fun in that? I'll let the following pictures show the space savings this new rack is allotting us.

One of our snake rooms before:

And after:

Now that I got this one knocked out, I just went and bought more shelving to get the second one built. While this new one took me several months to build, quite a bit of that time was spent exploring new methods of wiring as well as building the jigs to make the precision cuts. And even with the jigs and knowledge on how to now build this in a better more efficient way, it's still far from a simple weekend project, at least how I tend to overkill these things

The front:

Each shelf is routed out using a jig I made to make precise cuts to fit the tile and flexwatt.

The flexwatt bare:

The flexwatt covered with tile:

I'm not a big fan of butt joints, so I tend to dado everything!

Each shelf is dadoed:

My wiring scheme was really the biggest change in this 3rd generation of racks I've built. The top shelf wiring and bottom control shelf is the main wire while all shelves in the middle section have separate pieces of wiring soldered onto the main wire and coated using liquid electrical tape. It looks really basic on the back which is a far cry from my last rack whose wiring was a real nightmare to behold.

The back with wiring:

The bottom shelf is really a control shelf that is essentially the same as the others, only shallower using a small tub with the thermostat probe in it to monitor the temps. I once tried keeping a probe in an occupied tub heavily taped, but snakes have a funny way of fubar'ing anything you think you are clever in doing.

The bottom control section:

Each shelf is sized to house sterilite 41qt. tubs. I made a jig to help dado cut each side perfectly so that there is zero clearance between shelf and tub and yet there is no friction due to tightness, so removal is nice and smooth.

Half full with tubs:

Considering that our house has literally filled up with all of these large snake tanks, racks then became a much more idealistic solution to help alleviate the space management problems we are currently having. While it might be quicker, easier and even possibly cheaper buying a pre-made rack system, where's the fun in that? I'll let the following pictures show the space savings this new rack is allotting us.

One of our snake rooms before:

And after:

Now that I got this one knocked out, I just went and bought more shelving to get the second one built. While this new one took me several months to build, quite a bit of that time was spent exploring new methods of wiring as well as building the jigs to make the precision cuts. And even with the jigs and knowledge on how to now build this in a better more efficient way, it's still far from a simple weekend project, at least how I tend to overkill these things